ABS CF - 3D printing granulate with recycled carbon fibres (4 mm) for industrial and large format 3D printing on pellet extruders

ABS CF is a technical thermoplastic material designed for Large Format Additive Manufacturing (LFAM) 3D printing. It is an ABS granulate (acrylonitrile butadiene styrene) filled with recycled chopped carbon filaments with a length of 4 mm, developed for use in screw extruders and pellet-fed 3D printers. The material is ideal for applications where high stiffness, strength, thermal stability and dimensional accuracy of prints are required.

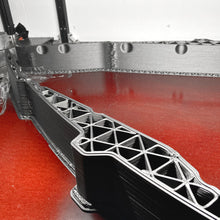

Our favourite material, from which we also print not only for our own needs, but also for customers such as the manufacturer of seats for rail vehicles and other components, the company ŽOS 4 TRAINS https://www.zos4trains.cz/, for which we have printed several sets of seats for trade fairs such as Rail Business Days 2025 in Ostrava and InnoTrans 2024 in Berlin.

✅ ABS material properties with carbon:

-

High stiffness and mechanical strength due to the addition of carbon fibre - ideal for functional parts and prototypes.

-

Lower weight compared to full plastic materials - carbon brings a strength-to-weight ratio similar to composites.

-

Increased dimensional stability - minimizes deformation and shrinkage during printing.

-

Better heat resistance than standard ABS - suitable for applications in harsher environments.

-

Increased print quality at high volumes - ideal for continuous industrial production.

-

Processing on industrial 3D printers with pellet input, e.g. Weber Additive, CEAD Flexbot, Caracol AM Heron, Titan Atlas, CMS kreator a3,

miniFactory Ultra Pellet and others.

-

Sustainable approach - the carbon fibre is recycled by us, helping to reduce the ecological footprint and verify the history of origin.

🏭 Typical applications and uses:

-

Printing moulds for laminating composites (e.g. for carbon or glass fibres - RTM, vacuum infusion, etc.)

-

Production of prototype parts with higher mechanical resistance and thermal stability.

-

Dimensional models and functional prototypes in the automotive, aerospace, construction or defence industries.

-

Shape-resistant parts for processing of composite materials - moulds, negatives, supports.

🧪 Material tested and verified:

The ABS CF material has been tested under operating conditions directly on Weber Additive and PIOCREAT G12 pellet 3D printers for industrial 3D printing from granules. The compound is stable, handles well and shows high reliability during long printing cycles. The long carbon fibers provide a better reinforcement effect than conventional short fillers.

📦 Available packaging and technical information:

- Packaging: bags of 25 kg or octabins

- Form: dry granulate suitable for direct processing in screw extruders

- Fiber length: 4 mm (recycled carbon fiber)

- Fibre content: 15%

- Compatibility:Weber Additive, CEAD and other LFAM systems

- Recommended printing temperature: 220-250 °C

- Nozzle and extruder temperature depends on the specific device

- Drying 80°C 4-8 hours

- Colour: black

Are you interested in a sample, a datasheet or a consultation on the suitability of the material for your application?

Contact us - we will be happy to advise you.

🔍 Keywords for easy search:

ABS carbon, ABS with carbon fiber, 3D printing granulate, pellet filament, LFAM material, CFRP, CFRTP, mold material, ABS recycled carbon, ABS carbon granulate, 3D printing compound, ABS carbon fiber reinforced, pellet 3D printing, ABS for large format printing, 3D printing from granules, 3D printing molds, carbon fiber to ABS, composite mold printing, ABS with reinforcement.