PETG GF15 - granulate for 3D printing with 15% glass fibre, made from recycled PETG

PETG GF15 is a technical granular material for large format 3D printing (LFAM) that combines recycled PETG polymer (polyethylene terephthalate-glycol) and 15% glass fibre. It is a sustainable and affordable 3D printing material suitable for industrial applications, technical prototypes, moulds and structural parts.

The material is optimized for use on pelletizing 3D printers with screw extruders (e.g. Weber Additive, CEAD, Piocreat G12, Titan Atlas, etc.).

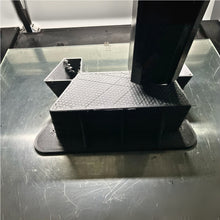

From PETG G15 we printed furniture - tables for the trade fair stand - FORMNEXT 2024 in Frankfurt https://formnext.mesago.com/frankfurt/en.html and JEC WORLD 2024 and 2025, the largest trade fair for composites in Paris https://www.jec-world.events/ .

✅ Advantages of PETG GF15:

-

Sustainability first - the basis is recycled PETG from industrial sources, thus reducing the ecological footprint of production.

-

Advantageous price/performance ratio - cheaper than pure engineering polymers but with excellent mechanical properties.

-

Increased stiffness and strength due to 15% glass fibre content - ideal for applications with higher demands on stability and dimensional accuracy.

-

Lower deformation during printing compared to conventional PETG - glass fibres significantly reduce shrinkage and ensure higher dimensional stability.

-

Excellent layer adhesion and good surface appearance - resulting in a strong, high-quality print even at larger sizes.

-

Compatibility with industrial pellet 3D printers - seamless material flow in screw extruders.

🏭 Typical applications:

-

Large technical prototypes and functional parts in the automotive, mechanical or electrical industry.

-

Printing of moulds and fixtures for the production of composite or plastic components.

-

Parts with higher thermal and dimensional stability that need to withstand mechanical loads and deformations.

-

Structural and assembly elements that need to be strong, but at the same time affordable.

🔬 Material composition and parameters:

-

Base polymer: recycled PETG

-

Filler: 15% glass fibre, chopped

-

Form: dry granulate suitable for extruders with pellet feed

-

Recommended printing temperature: 210-250 °C

-

Compatibility: Weber Additive, CEAD, Piocreat G12, Titan, miniFactory Ultra Pellet, BigRep and other LFAM systems

- Drying: 70-80°C 8-12h

-

Packing: 25kg, octabin

- Colour: grey

🌍 Environmental benefits:

-

✅ Recycled base polymer = smaller carbon footprint

-

✅ Less energy consumption in production than pure (virgin) polymers

-

✅ Fully processable in closed loop production systems

-

✅ Ideal for companies with a focus on sustainable development and responsible manufacturing

🔍 S earch engine optimization (SEO) keywords:

PETG GF15, PETG with fiberglass, 3D printing granulate, 3D printing compound, pellet material for 3D printing, sustainable 3D printing, granulate for pellet 3D printer, PETG with reinforcement, composite PETG, fiberglass in PETG, PETG recycled, cheap 3D printing material, eco-friendly filament, PETG with GF, PETG moulds, PETG for LFAM, granulate for screw extruder, recycled engineering plastic for printing.

Do you want to save money on materials but don't want to compromise on quality? PETG GF15 is your ideal choice.

For a sample, datasheet or customized offer, please contact us.